Référence

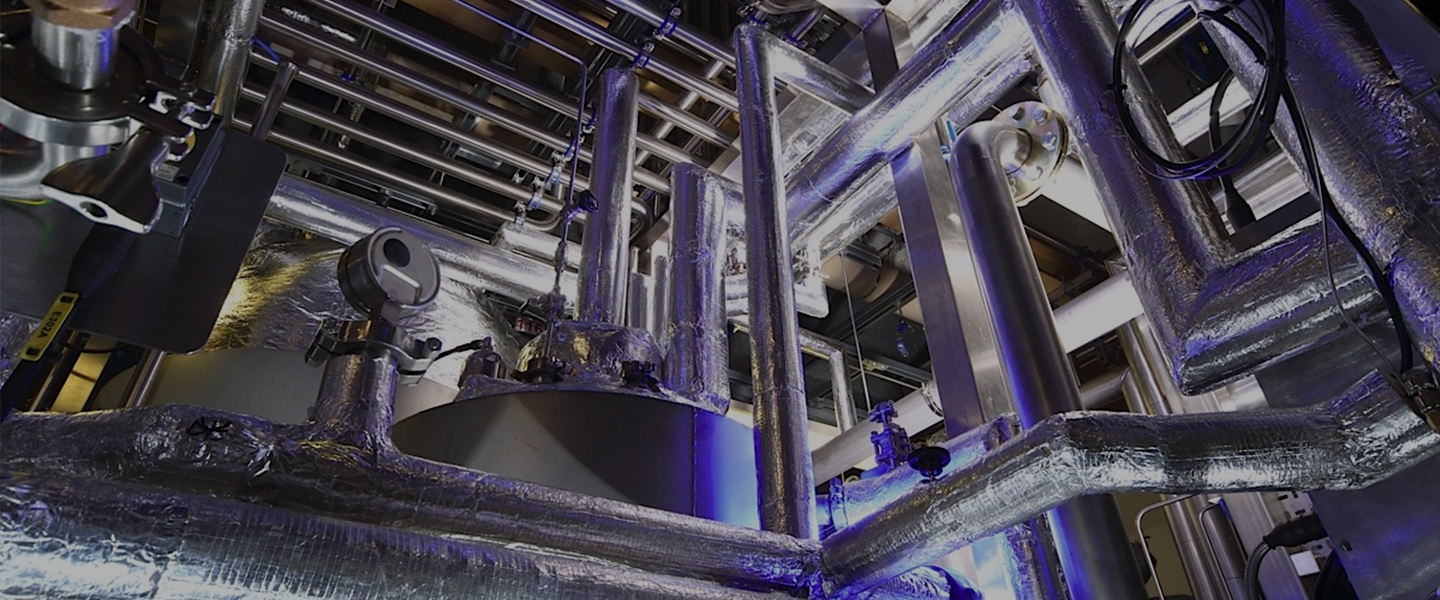

Biochemical Manufacturing Plant

Our client are a process technology licensing company, founded as a spin-out from Imperial College London. They strive to develop leading manufacturing technologies by using a combination of traditional chemistry and biochemistry approaches, to meet customer requirements for lactic acid and polylactic acid (PLA) production.

7

separate equipment skids

ATEX

rated conditions

Scale-up

capabilities

Our client’s aims are to enable partners to produce high value, renewable chemicals and ingredients, using feedstock of low value waste and industrial by-product streams. Our clieent therefore required the construction of a pilot plant, which would enable scale up of the laboratory process for proof-of- concept and would also improve manufacturing flexibility to maximise and optimise investment return.

Our Solution

Bouygues Energies & Services developed an innovative Design & Build solution for the pilot plant, based on modular process. Comprising of seven separate equipment skids, this design allowed for portability and also ease of expansion if necessary. The modular skids and vessels were prefabricated, prewired and pretested within our prefabrication facility in Knowlsey, Liverpool.

Based on our design and specifications, the pilot plant enabled a predictive scale up, to proof different stages of the process including; esterification, evaporation, bioreactors and distillation under ATEX rated conditions. As a result, the facility is designed and built to accommodate a wide variety of feedstock and produce bio-based chemicals, meeting client project proposals.

Benefits to the Client

A single point of accountability

Providing detailed design, architectural, procurement, construction, installation, process engineering, mechanical and electrical services, and commissioning to offer seamless engineering solutions to the challenges facing our client.

Quality at speed

An ultra fast track delivery, meeting project specifications and target costs while delivering world-class standard facilities, therefore minimising expense to the client.

Meeting industry demands

The versatility of the facility accommodates rapidly growing industry requirements such as automotive, personal care and aerospace, across high volume applications. This offers the client longevity for their facilities; they are able to expand as the client's portfolio expands.

Latest case studies

Our Commitments - Pharmaceuticals & Lifesciences

Our Commitments

De-risk Project Development

Accompanying you through the whole project development from concept stage to handover

Technical Expertise

Leveraging our engineering design and construction technique to accelerate and realise the vision of our clients

Compliance Strategies Within Regulated Sectors

Ensuring MHRA and FDA regulations are met as required

Lean Operation

Ensuring greater long-term operational efficiency and productivity

Latest news

Find all the topics that make Bouygues Energies & Services news: projects, innovations, public and client events, partnerships, press releases ...

There are no results for this choice