Case studies

University Research Facility

Our client specialise in stem cell research, with a Regenerative Medicine centre based at a UK University dedicated to the study and development of new regenerative treatments for human diseases. Their facility contains laboratory and support space, incubator units and a clinical translation unit containing high grade GMP cleanrooms, which facilitate the receipt of embryos from IVF clinics.

B, C & D

Cleanroom Grade

HVAC

systems

MHRA

compliant

The Regenerative Medicine Centre is the first large-scale, purpose-built facility of its kind in the UK and was the first laboratory building in Scotland to receive a BREEAM “Excellent” rating. Bouygues Energies & Services were appointed as the preferred contractor for the design, construction, commissioning and validation of all GMP areas, associated services and clean utility systems. The client required:

- Optimisation of the proposed design

- Construction of the GMP areas and installation of all associated specialist equipment including autoclaves, isolators, MBSCs, services and clean utilities

- Commissioning of HVAC Systems and associated utilities serving the GMP areas

- Validation of the clean rooms, services and utilities within the GMP areas

- Validation of equipment within the GMP areas

- Project management of the overall validation programme

Our Solution

Bouygues Energies & Services’ turnkey solution encompassed the design, construction, fit-out, commissioning and validation of the client’s high grade cleanroom, including EU GMP Grade B, C and D areas, with local Grade A environment in isolators and MBSCs.

The facility required a high level of services through mechanical and electrical plant, and as such the plant was located on a dedicated plant floor, sandwiched between the two research floors. All equipment and services were designed in order to facilitate access for operability and maintenance, without risking any compromise to the control measures required in GMP environments.

The internal fit-out and integration included the installation of autoclaves, process gas systems, and environmental monitoring system in line with current regulatory requirements, cryostorage facilities, and a walk-in cold room.

Bouygues Energies & Services in-house comprehensive regulatory compliance and validation support was provided to the client, including arranging a design review meeting with the MHRA. We provided a full validation service which included the generation of a Validation Master Plan and final Validation Summary Report. We were also awarded the Facilities Management contract for the planned maintenance and revalidation of the GMP areas of the facility.

Client Benefits

Single Point of Accountability

Providing detailed design, architectural, construction, procurement, installation, process engineering, mechanical & electrical services, commissioning and validation to offer seamless engineering solutions to the challenges facing our client.

Assurance of Compliance

A fully validated facility with successful HTA and MHRA inspections.

Value for Money

Bouygues Energies & Services’ holistic approach means that sub-contracting and external sourcing costs were minimised, as we took ownership of budget and cost overruns. It also meant we were able to deliver the project within a smaller time frame than competitors, ensuring the project was completed to time and economic constraints.

Optimised Usability

Access for operability was a full incorporated aspect of the design, ensuring optimal usability for the client.

Knowledge and Experience

Bouygues Energies & Services had the in depth knowledge of the facility to be able to provide a fully compliant Facilities Management package which included the requirements for facility revalidation.

Latest case studies

- Bouygues Energies & Services were approached to design and build their new data centre at VIRTUS' impressive Stockley Park Campus.Industry

- Bouygues Energies & Services were appointed as the turnkey partner for the refurbishment and upgrade of an operational computer room.Industry

- Bouygues Energies & Services were approached to design and build their new, flagship data centre in Hayes, London.Industry

- VIRTUS "energy efficient" data centre appointed Bouygues Energies & Services as their Design & Build partner.Industry

Our Commitments - Pharmaceuticals & Lifesciences

Our Commitments

De-risk Project Development

Accompanying you through the whole project development from concept stage to handover

Technical Expertise

Leveraging our engineering design and construction technique to accelerate and realise the vision of our clients

Compliance Strategies Within Regulated Sectors

Ensuring MHRA and FDA regulations are met as required

Lean Operation

Ensuring greater long-term operational efficiency and productivity

Latest news

Find all the topics that make Bouygues Energies & Services news: projects, innovations, public and client events, partnerships, press releases ...

-

-

-

-

-

-

-

-

-

-

-

-

-

- Learning at Work Week - Fostering a Culture of Continuous Learning & Development within the Business

-

-

-

-

-

-

-

-

-

-

-

-

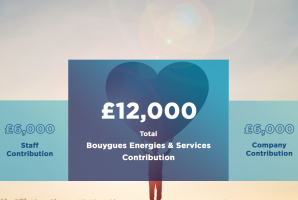

- Bouygues E&S Support for Parkinson's

-

-

-

-

- International Women's Day

- Climate Fresks at Bouygues E&S

-

-

-

-

- Investing in our people to train the next generation of talent and further the skills of our employees

-

-

-

-

-

-

-

- International Men's Day

-

-

-

- Bouygues E&S continues to foster and develop relationships with extremely worthwhile causes.

-

-

- Bouygues E&S is taking action to transition our fleet to electric vehicles and installing the infrastructure to support this.

-

-

- Bouygues E&S' fundraises for Wear It Pink.

-

-

-

- Last month, Bouygues E&S hosted our first Apprenticeship Induction Day.

- Bouygues Energies & Services advocates its support for mental health services across the UK and within our business.

-

-

- Graduates raise over £4,000 for this important cause.

-

- This National Inclusion Week, Bouygues E&S are particularly proud of its overarching D&I Champions Network.

-

-

- This European Mobility Week, Bouygues Energies and Services is shining the light on key business initiatives.

- Bouygues E&S recently held its first internal ‘Apprentice of the Year Awards’...

-

-

-

- Bouygues E&S celebrates first-ever TopSite award!

- We are excited to announce the launch of Orbiter™ by Bouygues Energies & Services.

-

-

-

-

- Supporting Digital Transformation for Improved Decision-Making and Building Performance Optimisation

- At BYES, we are committed to championing gender equality.

- By supporting them to achieved their Uptime Institute accreditation

-

-

- The School is the result of a collaboration between clients, contractors and suppliers

-

-

-

-

- International Women’s Day #BreakTheBias

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- Today is ‘Earth Overshoot Day’. This is the point in each year when humans have used up a full year’s worth of resources

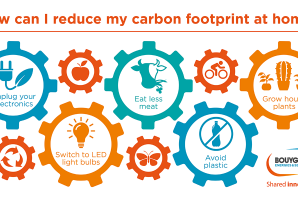

- At Bouygues Energies & Services, as well as increasing the electric vehicles in our fleet and using telemetry to enable more efficient driving, we also equip our staff with tips to help reduce their carbon footprint while on the road. If you’re keen to reduce your carbon footprint while driving, here are some key tips that will also save you money on your fuel bill in the process!

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- TO STRENGTHEN ITS EXPERTISE IN INDUSTRY 4.0

-

-

-

-

-

-

-

-

-

-

- Bouygues Energies & Services have helped plant over 235 trees in Malawi with the help of Fruitful Office

-

-

-

-

-

- Earlier this week we spoke to Jo Adams, one of our lead Interior Designers

-

-

-

-

-

-

- Bouygues Energies & Services support Bouygues Construction is continuing to sow its seeds in Australia.

- Each year we hold our internal Sustainability Awards open to all our people within Bouygues & Energies Services UK.

-

- Food sustainability is about culture, health, equity and respect for the planet we live on.

- We see you as more than a number…

- Interview with Adeel Aslam, Technical Director, Bouygues Energies & Services, Contracting

- where we provided a solution to help improve the internal air quality

-

- 7100 m² of data storage in the heart of Marseille’s port district

-

- One for the diary, 11th November 2020, 2pm - 3pm (GMT)

- Provide renewable energy produced from the North Sea Wind Farms to homes across Germany by 2024.

-

-

- Pre-fabrication modular block: The paradigm shift to build a data centre differently?

- A virtual celebration to thank our supply chain

-

-

- Find out why we're prioritising electric vehicles

-

-

- There has always been a huge importance on reducing our Global footprint, to ensure a sustainable future

- A day for employers across the country to advocate their support for responsible employment.

- We have signed a first of its kind deal with Airlite, an innovative paint company

- Top tips to reduce you carbon footprint while working from home

-

- Along with 17 other companies the Data Centre team undertook a number of high-level fundraising activities in aid of CRASH charity.

- On this project we will be using our new innovative modular solution to help achieve the quality, speed to market..

- Sustainability can be a uniting theme and in this context great partnerships can be built between universities and the private sector.

- Leon wins the Sustainability Awards!

- We've helped Manchester Cares get closer to their £10,000 target

-

- We're providing a safe long term solution to protect our healthcare workers

- We’ve contributed to over 23,000 fruit portions, 600 fruit baskets being delivered to NHS hospitals.

- Some of our team members share their experiences during Covid-19.

- We've been recognised for our approach to health and safety

- Well done to our four team members that have made the finals!

-

- The Most Effective Development to a Wellbeing Strategy

- ExCel London on the 11th – 12th March 2020

- Bouygues Energies & Services are Exhibiting at this year’s Data Centre World

-

-

-

-

-

- Project Manager Aaron Yule will lead the team in charge of transforming Ashford's lighting.

-

-

-

-

-

- Gold Award for our continued focus on sustainability

- We're exhibiting at this year’s 2019 ISPE Europe Pharma 4.0 Conference, 20 - 21 November 2019, Manchester, Old Trafford.

- We have successfully renewed our Cyber Essentials Plus certification for the whole organisation.

- Virology Research Laboratory extension for AstraZeneca

-

-

- Bouygues Energies & Services are Exhibiting at this year’s DCD Event, 5 -6th November 2019, Old Billingsgate, London.

- David Carr presents his thought leadership piece.

- VIRTUS is the fastest growing Data Centre provider in the UK.

- We're encouraging our staff to share their work stories on social media.

- Bouygues Energies & Services are pleased to announce they are supporting DATACENTRE.ME!

- We're developing an energy project that will transform St Ives Park & Ride into a renewable energy generator.

- We will be presented the award by HRH Princess Anne

-

- Bouygues Energies & Services get moving with the Virgin Pulse

- Bouygues Energies & Services Data Centre team took part in The 21st Dragon Boat Challenge.

-

-

- We're looking for innovative startups to help create the campus of tomorrow!

- We hosted a construction skills academy for local people in Tower Hamlets.

- We're supporting the special Olympics and the great work it does to support 10,000 athletes.

-

- Brent are saving money, saving carbon and creating a safer place to live and work.

-

- Working with young people means that for us, wellbeing is as much of a priority as security.

- Employees have been busy spreading the festive cheer, with Christmas fundraising.

- We have won the award in recognition of our sustainability initiatives.

- We are collaborating with the whole Bouygues Construction Group in the UK to host Health & Safety Day 2018.

- Bouygues Energies & Services are delighted to announce the successful handover of the VIRTUS LONDON5 facility.

- With Sun'R we have combined our skills to support Lamagistère in its energy transition.

- We continue to grow our successful partnership, with further orders from VIRTUS.

- Axione becomes the 86th member of the altnet cooperative.

- Commercial partnership signed between us and Bosch France

- James Williams tells us about his role at Bouygues Energies & Services as a Process Engineer.

- We are delighted to announce a new contract with VIRTUS Data Centres.

- Sustainability initiative for Chelsea and Westminster NHS Foundation Trust.

- What makes a 'good' data centre?

- Bouygues Energies & Services commits to eliminating all single-use plastics from supply chain.

- What do our apprentices really think?

- with Geology graduate, Connor Cassley.

- Bouygues Energies & Service feature in Innovators magazine's biotech special.

- with Interior Architecture and Design undergraduate, Hollie.

- Graduate Trainee, Chris Nicolaou, talks about his experience working in Procurement.

- Bouygues Energies & Services awarded FM Contract with Slough Borough Council

- Bouygues Energies & Services is delighted to achieve certification of the revised ISO 9001 and ISO 14001.

- Bouygues Energies & Services awarded new contract to continue providing Facilities Management to UAL.

- Bouygues E&S Contracting UK Ltd win prestigious RoSPA Gold Award

- Bouygues Energies & Services celebrate the grand opening of our new Scottish office.

- Bouygues Energies & Services engineers go back to school to inspire the next generation of engineers.

- Bouygues Energies & Services partner with Flybits to deliver the connected workplace of the future.

- Bouygues Energies & Services celebrate female engineers on international Women In Engineering Day.

- Bouygues Energies & Services win Considerate Constructors Scheme Bronze medal.

- Bouygues Energies & Services are showcasing at Data Centre World 2017

- We have delivered a £1.3M refurbishment at Barnet Hospital.

- Bouygues Energies & Services Partnering Approach with Biotechnology Stakeholders.

- We're proud to be on the CCS’ TMT2 Framework Agreement.

- Strengthening Supply Chain Partnerships Under the Wings of Concorde

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256 257 258 259 260 261 262 263 264 265 266 267